Ein Berliner Unternehmen mit Tradition

NOVAPAX ist ein mittelständisches Familienunternehmen, das 1949 gegründet wurde, seit 75 Jahren besteht und seinen Standort in Berlin hat.

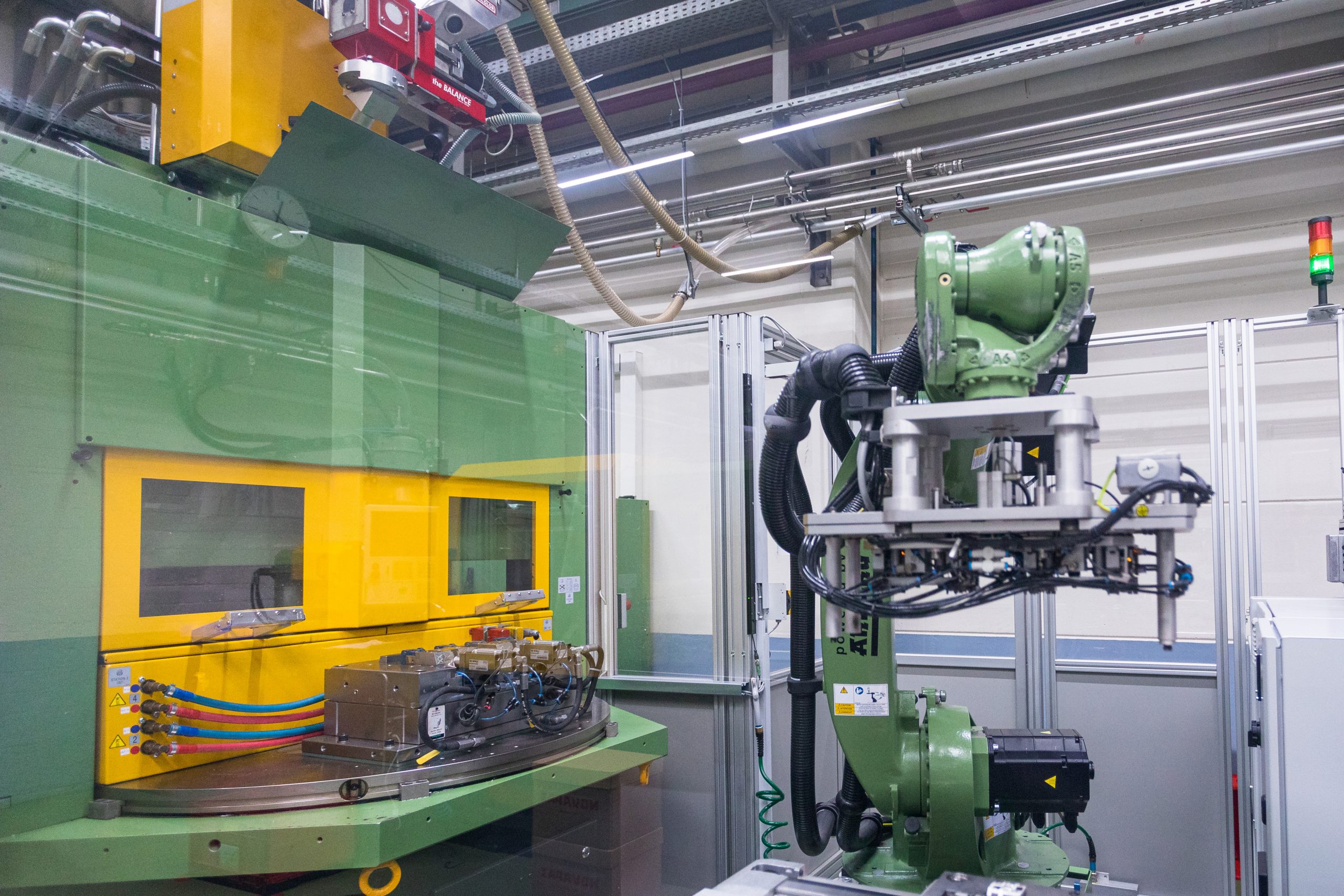

Als Experte für die Herstellung und Lieferung von Komponenten und Formen für Kunststoffteile ist NOVAPAX langjähriger Partner seiner international agierenden Kunden in Automotive, in der Elektro- bzw. Elektronik-Industrie und diversen anderen Branchen.

Entwicklung, Formenbau und Spritzgussproduktion liegen in einer Hand und bilden ein starkes technologisches Fundament.

Den Kunden wird ein durchgängiges Leistungskonzept geboten. Aus neuestem effizienten Einsatz, Fertigungstechnik und Automatisierung werden technische Komponenten und Baugruppen entwickelt, um im internationalen Wettbewerb bestehen zu können.

Bei EnterTechnik können sie sich ausprobieren und entdecken, was Spaß macht, bevor sie sich für einen Berufsweg entscheiden.

NOVAPAX bietet ihnen die Chance, ihren eigenen Zugang zur Welt der Technik zu finden. Jetzt bewerben!

Projekt 1114-B1-E Zentrale Materialversorgung ZMV

Im Rahmen des BENE-Förderprogramms wurde die Zentrale Materialversorgung aus Mitteln des EFRE und des Landes Berlin unter der Projektnummer 1114-B1-E gefördert.

Die ortsfeste Zentrale Materialversorgung ist speziell für die Produktionsanlagen von Fa. Novapax ausgelegt und entworfen worden. > weiter lesen

Die Förderanlage wird maschinenbezogen ausgeführt, d. h. je Verarbeitungs- maschine wird eine Materialleitung von der zentralen Kupplungsstation mit diversen Abgängen zur Maschine geführt. Die Beschickung der Trockentrichter und der Verarbeitungsmaschinen erfolgt über separate Förderkreise mit selbstreinigenden Filtern. Die Förderung zu den Verarbeitungsmaschinen erfolgt im geschlossenen Kreislauf mit rezirkulierter Luft. Durch die zentrale, frequenzgeregelte und damit lastabhängigen Luftmengenregelung wird eine erhebliche Energieeinsparung gegenüber den vorhandenen mobilen Trockenaggregaten erzielt und die Effizienz des gesamten Materialhandlings erheblich erhöht. Die Energieeinsparung wird abhängig vom Lastkollektiv und Material voraussichtlich bei über 60 % gegenüber den Einzelgeräten liegen.